MXR Technology LLC is a leader in Motionless Mixers for turbulent and laminar flow.

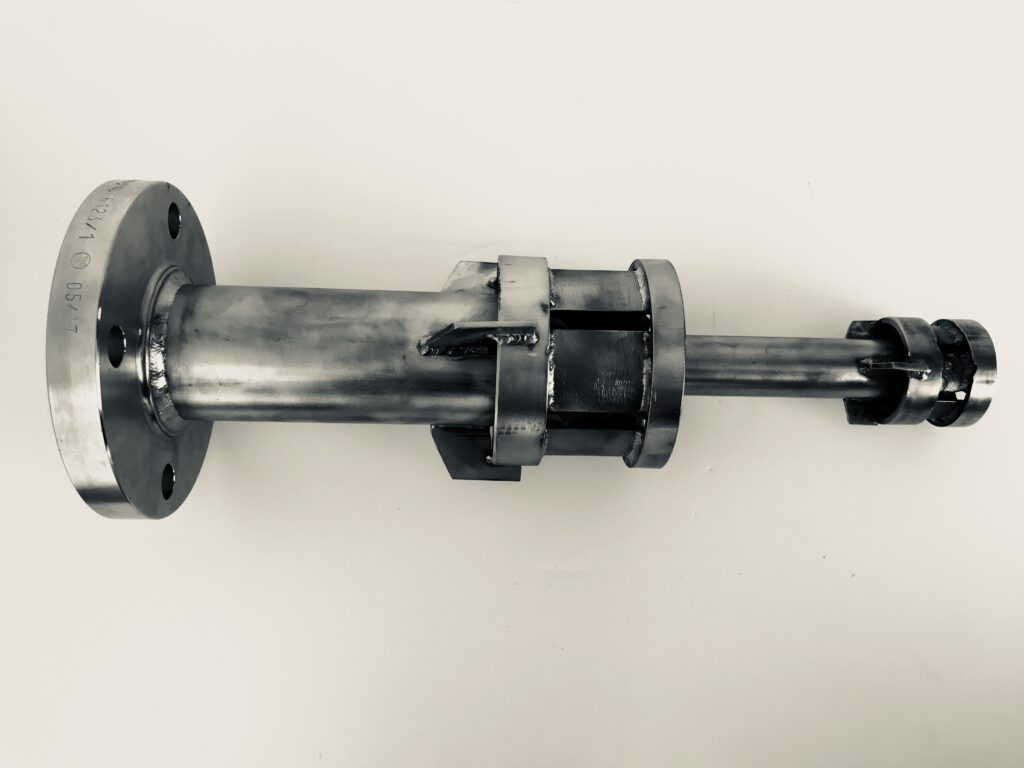

The Type “TH” Tank Heater is custom-engineered for direct injection of steam into a tank containing water/liquid. No moving parts, no noise, and no vibration. Each unit employs 1 or 2 specially designed mixing modules to equally disperse the steam inside the tank. Typical Steam Heating application includes direct injection of steam into the tank to produce hot water in Chemical Plants, Oil Refineries, Oil & Gas Plants, Food Processing, Mining, Pulp & Paper Mills for heating process water. The design flexibility of MXR’s Tank Heating Technologies will provide superior heating performance in any tank heating application. Standard Material of construction is Type 316/L Stainless Steel. Available in pipe sizes from 2″ to 12″ diameter.

General Applications – Water Heating:

Industrial Applications

A wide variety of industrial process applications take advantage of tank heating technology including:

North & South America

MXR Technologies LLC

40515 Green Oaks Dr.

Temecula, California, 92592 USA

Asia Pacific & Europe

MXR Technologies LLC

Paratong, Sta. Cruz, llocos Sur

Philippines

© 2014 – 2024 MXR Technologies LLC

Static Mixing, Reaction, Heat Transfer & Fluid Dynamics Technology

All Trade Marks are Property of their repective holders.

Privacy Policy | Powered by Ortiz Design