MXR Technology LLC is a leader in Motionless Mixers for turbulent and laminar flow.

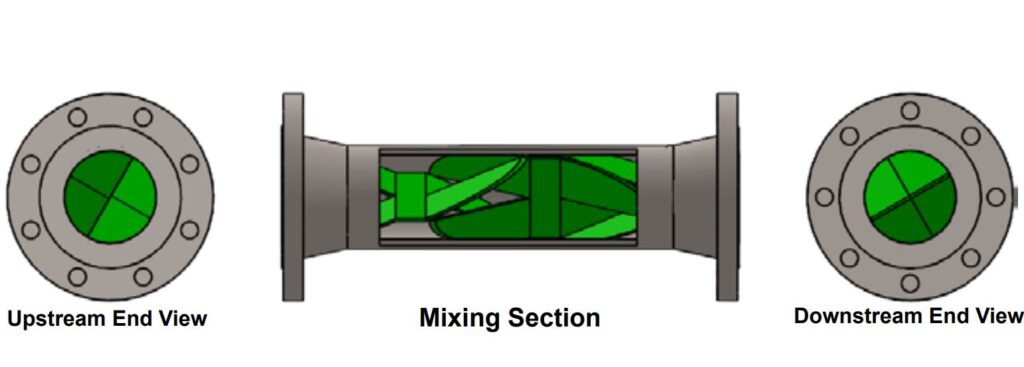

The Type “CM” Custody Transfer Mixers employ a simple design to provide the ultimate in mixing. Each unit achieves high mixing efficiency through multiple-action mixing. The crude oil and water content are mixed through equal division, re-division and rotational mixing which enhances turbulence and mixing. This results in complete uniformly mixed product at the outlet. The “CM” Custody Transfer Mixer is used when accurate sampling is required such as in the custody transfer of crude oil from either ship to shore or storage facility to another. The design flexibility of MXR’s Mixing Technologies will provide superior mixing performance in Custody Transfer Applications. Standard Material of construction is Carbon Steel. Available in pipe sizes from 3/4″ to 60″ diameter.

MXR has designed and manufactured the CM250 Series providing superior mixing performance in Custody Trasnfer Applications.

A wide variety of process applications take advantage of static mixing technology including:

Industrial Applications

Process industries utilize static mixers in a broad range of applications such as:

The design flexibility of MXR’s Mixing Technologies will provide

superior mixing performance in Custody Transfer Applications.

CM250 Series

| Line Size (NPS) | Model No. | Length (Inches) |

| 3/4 | CS0075-040-02CM250-EA | 2.81 |

| 1 | CS010-040-02CM250-EA | 3.49 |

| 1 1/2 | CS015-040-02CM250-EA | 5.18 |

| 2 | CS020-040-02CM250-EA | 7.42 |

| 3 | CS030-040-02CM250-EA | 9.94 |

| 4 | CS040-040-02CM250-EA | 13.07 |

| 6 | CS060-040-02CM250-EA | 19.61 |

| 8 | CS080-040-02CM250-EA | 25.81 |

| 10 | CS100-040-02CM250-EA | 32.23 |

| 12 | CS120-STD-02CM250-EA | 38.47 |

CM250 Series

| Line Size (NPS) | Modle No. | Length (Inches) |

| 3/4 | CS0075-040-03CM250-EA | 4.07 |

| 1 | CS010-040-03CM250-EA | 5.07 |

| 1 1/2 | CS015-040-03CM250-EA | 7.57 |

| 2 | CS020-040-03CM250-EA | 10.54 |

| 3 | CS030-040-03CM250-EA | 14.48 |

| 4 | CS040-040-03CM250-EA | 18.89 |

| 6 | CS060-040-03CM250-EA | 28.52 |

| 8 | CS080-040-03CM250-EA | 37.34 |

| 10 | CS100-040-03CM250-EA | 46.88 |

| 12 | CS120-STD-03CM250-EA | 55.85 |

North & South America

MXR Technologies LLC

40515 Green Oaks Dr.

Temecula, California, 92592 USA

Asia Pacific & Europe

MXR Technologies LLC

Paratong, Sta. Cruz, llocos Sur

Philippines

© 2014 – 2024 MXR Technologies LLC

Static Mixing, Reaction, Heat Transfer & Fluid Dynamics Technology

All Trade Marks are Property of their repective holders.

Privacy Policy | Powered by Ortiz Design