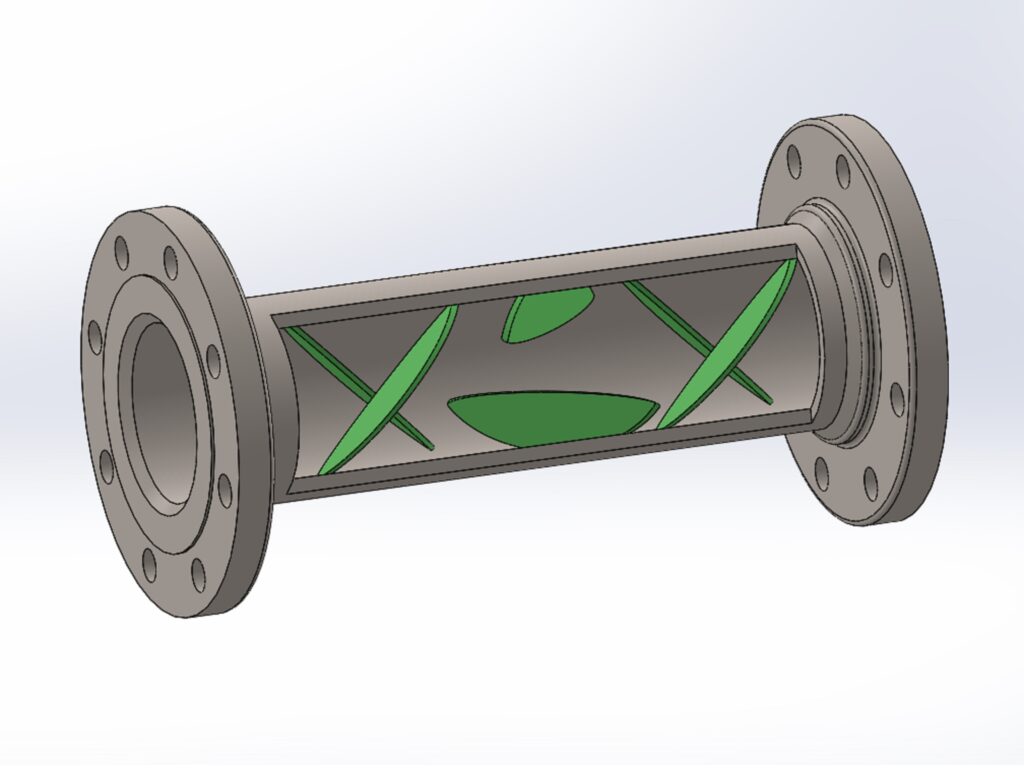

MXR Technology LLC is a leader in Motionless Mixers for turbulent and laminar flow.

A wide variety of process applications take advantage of static mixing technology including:

North & South America

MXR Technologies LLC

40515 Green Oaks Dr.

Temecula, California, 92592 USA

Asia Pacific & Europe

MXR Technologies LLC

Paratong, Sta. Cruz, llocos Sur

Philippines

© 2014 – 2024 MXR Technologies LLC

Static Mixing, Reaction, Heat Transfer & Fluid Dynamics Technology

All Trade Marks are Property of their repective holders.

Privacy Policy | Powered by Ortiz Design